![]() Wood processing

Wood processing

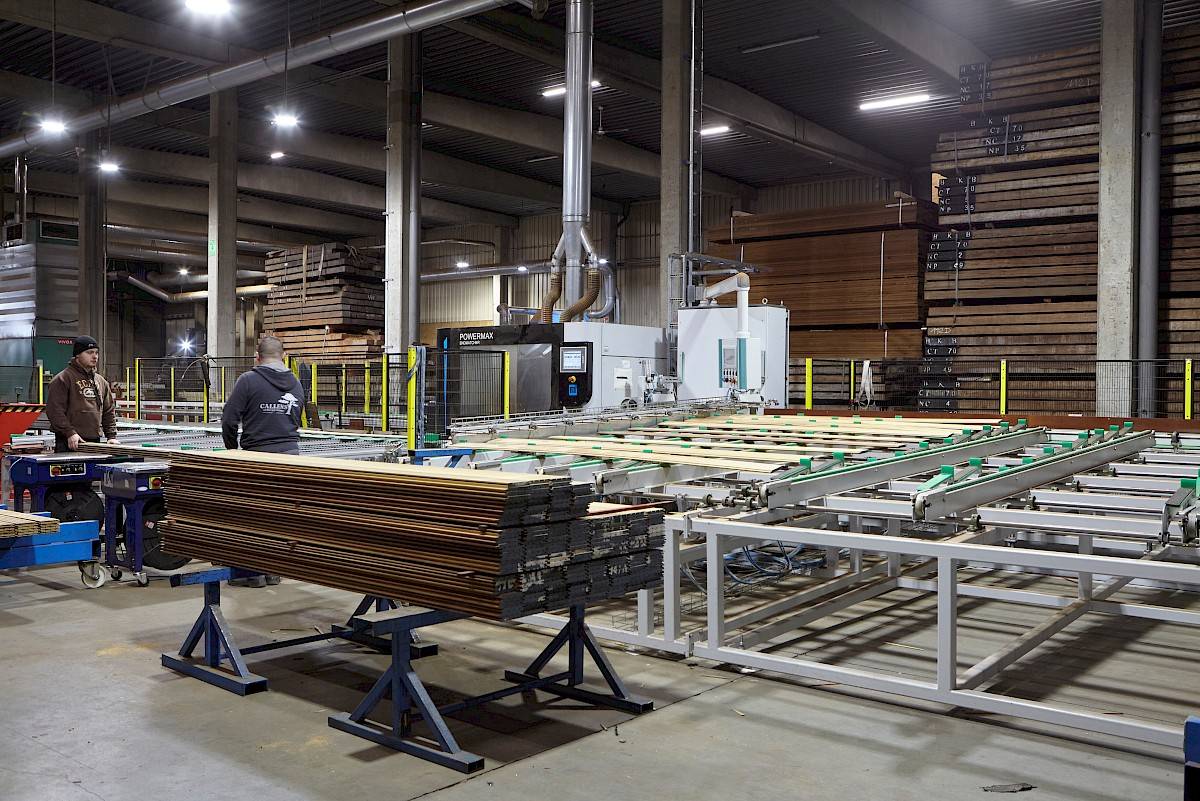

In our state-of-the-art and versatile workshop in Rekkem, we process more than 30 different types of African hardwood on a daily basis, tailored to your project, with a focus on precise finishing and swift delivery.

Our enthusiastic sales and production team actively collaborates with you to look for the best and most cost-effective solution for your finished or semi-finished products. As a customer of Callens African Woods, you can count on clear agreements, excellent finishing quality, and prompt delivery times.

![]() Operations

Operations

Sawing and resawing

Saw blades and cutting speed are adjusted to the nature, hardness and moisture content of the wood. Thanks to our two state-of-the-art sawing machines, including the new Twin-Stenner with double band saw, we are able to perform various customized sawing jobs quickly and accurately, and guarantee excellent quality.

Planing

Thanks to a 9-axis four-sided planer, we are able to produce complex profiles effortlessly. For planing heavy lumber, we invested in a modern and powerful short planer with floating spindles. A potent machine that can process packs of wood with falling widths effortlessly.

End finishing

Callens African Woods invested in a high-tech endmatcher that performs various end operations in a continuous cycle. Suitable for end grooving decking boards and facade planks. Various types of profiles are sawn on demand. We deliver the semi-finished products, so that you as a customer save on time, work and costs.

Thermal treatment

Through thermal treatment, we modify African wood species with a durability class of 4, such as Ayous or Fraké, and achieve a higher durability class.

With this process, we meet the demand to provide an environmentally friendly alternative.

Crosscutting

Crosscutting involves sawing the wood in the width direction, perpendicular to the grain. An advanced crosscut saw allows us to efficiently and quickly trim full bundles to the desired length. Precisely crosscutting to a specific length is also possible.

Finger jointed and laminated wood

We have a large stock of semi-finished products in various shapes and wood species. Frequently requested types are the solid finger-joined SAPELLI, SIPO and IROKO products under the KOMO product certificate.

We also supply products such as KKK (finger-joined-glued wood) and DKD (laminated wood). Semi-finished products that guarantee top quality with minimal material loss during processing.

![]() CE-markeringen

CE-markeringen

At Callens African Woods, we always provide the most suitable solution. Quality of finish and durability of the final product are our priority. Do not hesitate to submit your projects to us, together we can find the best solution.

Newsletter

Subscribe to our newsletter and receive the latest news from the industry, information about our species of wood, vacancies or upcoming events.

Never miss an update!